- Hypercube corexy drivers#

- Hypercube corexy driver#

- Hypercube corexy 32 bit#

- Hypercube corexy software#

I've been working out the geometry for a modular y-carriage design for the SolidCore printer. Some will jump forwards or backward after a number of power cycles. When powered up stepper motors tend to jump to the four steps that match the phase current.

Hypercube corexy 32 bit#

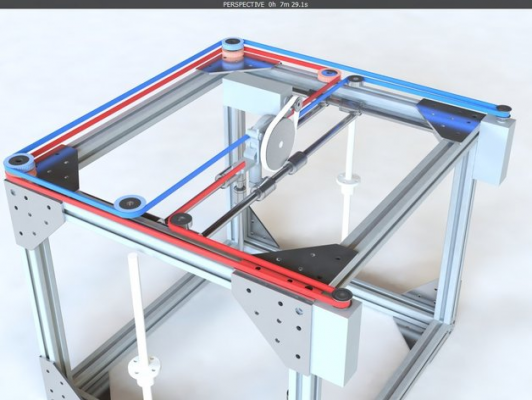

But with a good electronics setup like the 32 bit Duet board and the RepRap Firmware keeping the three lead screws in sync should be fie. Many 3d printer users frown upon the idea of multiple steppers for independent z motors due to syncing issues. Duet 3 Mainboard H6C - RepRap Firmware Duet 3 Mainboard H6C - RepRap Firmware RepRap Firmware: Independent Z Motors But after having trouble sourcing the belt that was the perfect length I decided to just go with three stepper motors similar to the HeVort printer or Jubilee tool changing core xy platform. Originally we were working on a design that used this single z-axis motor configuration. The typical core-xy 3d printer parts arrangement has a single NEMA 17 stepper motor with the belt routing to all two or three lead screws which move together in sync. Single Z-Motor vs Triple Z-Motor Single Z-Motor vs Triple Z-Motor With the Duet Wifi we can drive 3 steppers and run an auto bed leveling routine using a proximity sensor or probe. Each lead screw will be constrained by an MGN12 linear rail. The belt to lead screw arrangement also minimizes and vibrations that might be transferred from the motors to the z-axis. I’m not an engineer but I think that the belt and pulley ratio gives the steppers more torque and increases resolution. We’re planning to use a 3 independent z-axis setup on the SolidCore 3D Printer. Triple Z-Axis / Belted Z Triple Z-Axis / Belted Z TripleZ-Motors The major benefit of the design is that the motors remain in a static position. This means rapid acceleration because the two stepper motors provide a means of moving both axes independently or simultaneously. The corexy parallel kinematics mean’s that the motors are the largest source of inertia within the system, are stationary. Think of it as an ecosystem of parts that can be arranged in different configurations and adapted for unique applications. Our long term goal is to is to build a modular platform, not just a printer. You then specify the max dimensions for each axis in the firmware and software, but these values are easy to change if you ever need to adjust them.SolidCore CoreXY CAD Design In Fusion 360 I’d recommend if you’re building the printer yourself, make a mockup in a CAD program so you test for how it will be put together and how much travel you have in each axis.

Hypercube corexy driver#

So you could use just 3 endstops and have it calculate max dimension for when the driver detects skipping.

Hypercube corexy drivers#

Essentially the drivers monitor the current from the motor and if they detect an error caused by the motor skipping it feeds this information back to correct for the skipped steps.

You’ll also need an expansion board to detect all those endstops because most control boards don’t give you that many ports.Īnother way would be to build the printer with skip correction using closed loop drivers which use an amp to loop back current for positional detection.

In order to do this you need a max and min endstop for X, Y, and Z which I believe is just overkill because you’ll do nothing with half the endstops besides figure out the build volume.

Hypercube corexy software#

Let’s say you use 1 endstop per axis like most 3D printers (1 limit switch for x, 1 for y, and a probe for z) and all are set to home to the 0 position (front left corner of build plate) if you try just to detect X max and you know it’s somewhere between 200 and 250 mm, you tell the software to move the head 250 mm and say it’s actually 230, the X motor will just skip steps for the last 20 mm and the controller will be none the wiser (unless you have skip sensing with closed loop control) because there’s no endstop to detect when the printer has reached the max value. Well unless you have an endstop at the min and max of each axis of the printer there’s really no way to calculate this.

0 kommentar(er)

0 kommentar(er)